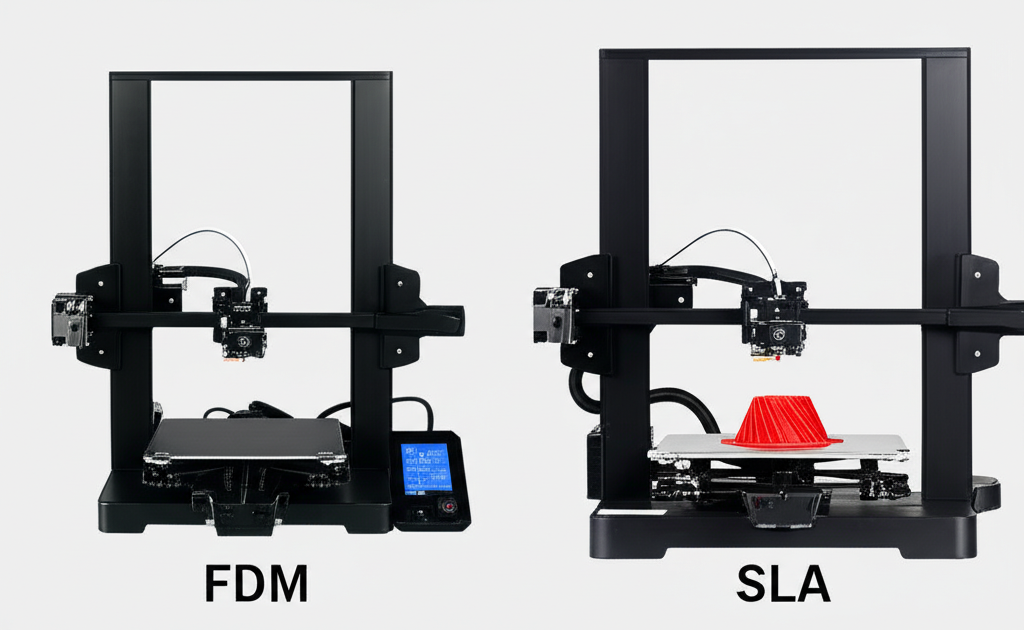

FDM vs SLA Printers: What to Choose in 2024

FDM and SLA represent two different philosophies of 3D printing. Each technology has its advantages and disadvantages. In this article, we'll compare both technologies in detail to help you make the right choice.

How it works:

A plastic filament is heated in the extruder and extruded through a nozzle, forming an object layer by layer on a moving platform.

Materials:

PLA, ABS, PETG, TPU, Wood, Metal-filled and many others

How it works:

A UV laser or LCD screen exposes liquid resin, curing it layer by layer. The platform rises, forming the finished object.

Materials:

Standard resin, Tough, Flexible, Castable, Ceramic-filled

Detailed Comparison

| Characteristic | FDM | SLA | Winner |

|---|---|---|---|

| Printer Cost | $150-500 | $200-800 | FDM |

| Material Cost | $20-30/kg | $50-80/L | FDM |

| Surface Quality | Visible layers | Smooth surface | SLA |

| Detail Level | 0.1-0.3mm | 0.01-0.05mm | SLA |

| Build Volume | Up to 300x300x400mm | Up to 200x200x250mm | FDM |

| Safety | Safe | Toxic resin | FDM |

When to Choose FDM

- • Functional parts: cases, mounts, tools

- • Large objects: vases, decor, prototypes

- • Learning: safe for children and beginners

- • Limited budget: low cost of printer and materials

- • Material variety: from flexible to reinforced

When to Choose SLA

- • High detail: miniatures, jewelry

- • Smooth surface: no visible print layers

- • Small details: complex geometry and thin elements

- • Professional applications: dentistry, medicine

- • High precision prototypes: for casting and molding

Conclusion

The choice between FDM and SLA depends on your specific needs. FDM is better for beginners, functional parts, and limited budgets. SLA is ideal for highly detailed models and professional applications, but requires more attention to safety and post-processing.

Our Recommendation

For your first printer, choose FDM. After mastering the basics of 3D printing, you can decide if you need an SLA printer for specific tasks requiring high detail.