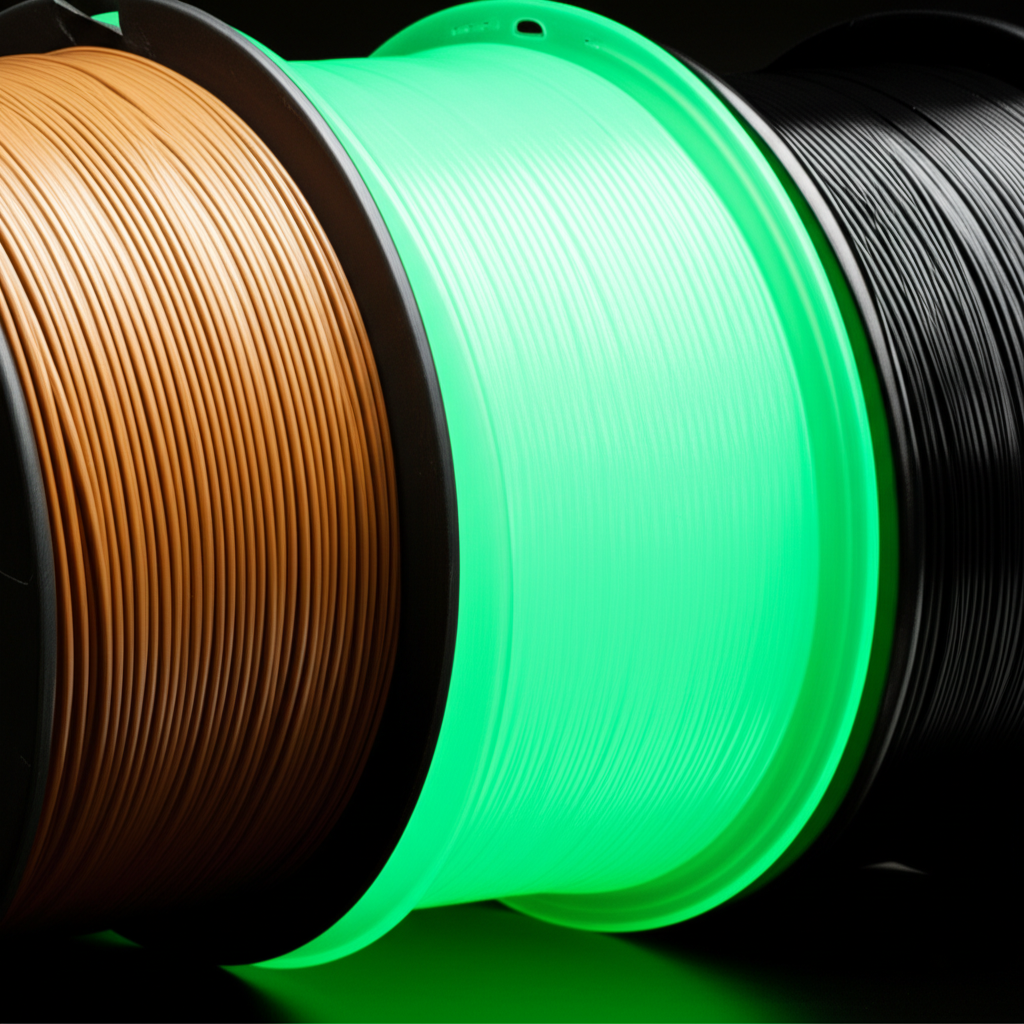

Special Filaments: Wood, Metal, Carbon Fiber

Special filaments unlock new possibilities for 3D printing, enabling the creation of items with unique properties and appearances. From wood composites to carbon fiber, each material has its own characteristics and applications.

Overview of Special Materials

Properties:

Advantages:

- ✓Can be sanded and painted

- ✓Pleasant smell during printing

- ✓Unique texture

- ✓Easily processed with tools

Disadvantages:

- ✗May clog nozzle

- ✗Requires larger nozzle (0.6mm+)

- ✗Less durable than standard PLA

- ✗Moisture-sensitive

Applications:

- •Decorative items

- •Furniture elements

- •Artistic projects

- •Prototypes of wooden products

💡 Printing Tip:

Use a 0.6mm or larger nozzle, print slowly (30-40mm/s)

🏭 Recommended Brands:

Properties:

Advantages:

- ✓Heavier than regular plastic

- ✓Can be polished to a shine

- ✓Metallic appearance

- ✓Good thermal conductivity

Disadvantages:

- ✗Abrasive to nozzle

- ✗Expensive

- ✗May delaminate

- ✗Requires steel nozzle

Applications:

- •Decorative items

- •Jewelry prototypes

- •Collectible models

- •Artistic sculptures

💡 Printing Tip:

Always use a steel nozzle, print slowly

🏭 Recommended Brands:

Properties:

Advantages:

- ✓Exceptional strength

- ✓Lightweight

- ✓High stiffness

- ✓Heat resistance

Disadvantages:

- ✗Highly abrasive

- ✗Expensive

- ✗Requires special nozzle

- ✗Difficult to print

Applications:

- •Drones and quadcopters

- •Automotive parts

- •Sports equipment

- •Engineering prototypes

💡 Printing Tip:

Use a hardened steel nozzle, enclosed chamber

🏭 Recommended Brands:

Properties:

Advantages:

- ✓Glows in the dark

- ✓Easy to print

- ✓Safe

- ✓Unique effect

Disadvantages:

- ✗Weak glow

- ✗Requires 'charging' with light

- ✗Limited colors

- ✗Can be abrasive

Applications:

- •Toys

- •Decorative elements

- •Emergency signs

- •Nightlights

💡 Printing Tip:

'Charge' the item with bright light before use

🏭 Recommended Brands:

Post-Processing of Special Materials

- 1Sanding with sandpaper (220-400 grit)

- 2Wood stain or paint

- 3Varnish or wax for protection

- 4Can be carved with tools

- 1Sanding with fine sandpaper

- 2Polishing with metal paste

- 3Patination for an aged effect

- 4Protective coating against oxidation

- 1Minimal post-processing

- 2Light sanding if necessary

- 3Avoid aggressive processing

- 4Protect against dust during sanding

Equipment Requirements

Important Requirements:

Nozzles:

- • Wood PLA: Brass 0.6mm+ or steel

- • Metal-filled: Hardened steel required

- • Carbon Fiber: Hardened steel or ruby

- • Glow: Brass or steel

Additional:

- • Heated bed for better adhesion

- • Enclosed chamber for Carbon Fiber

- • Ventilation when working with composites

- • Protective gear during post-processing

Cost and Efficiency Comparison

| Material | Price/kg | Difficulty | Uniqueness | Application |

|---|---|---|---|---|

| Wood PLA | $25-35 | Easy | High | Decor, hobbies |

| Metal-filled | $40-60 | Medium | Very High | Decor, prototypes |

| Carbon Fiber | $60-100 | Difficult | Medium | Functional |

| Glow-in-Dark | $30-45 | Easy | High | Decor, toys |

Safety During Operation

- • Use ventilation when printing composites

- • Wear a mask when sanding Carbon Fiber

- • Safety goggles during post-processing

- • Gloves when working with abrasive materials

- • Regularly replace nozzles after abrasive materials

- • Clean extruder from composite residues

- • Check wear on filament guides

- • Calibrate printer after material change

Conclusion

Special filaments open up endless possibilities for creativity and functional applications. Wood PLA is ideal for decorative projects, Metal-filled creates stunning visual effects, Carbon Fiber provides maximum strength, and Glow-in-the-Dark adds a touch of magic to your creations.

Recommendation for Beginners

Start with Wood PLA—it’s forgiving and yields impressive results. Once mastered, move to Metal-filled for unique decorative items. Save Carbon Fiber for later, when you’ve gained experience.